RECOMMENDED AMMUNTION FOR USE IN THE PSG 22

BRAND | TYPE |

|---|---|

| Remington | |

| Federal | |

| CCI | |

| Aguila |

"*" indicates required fields

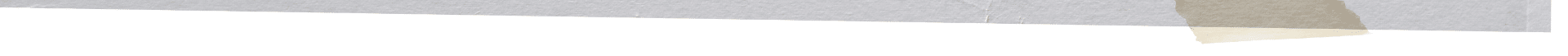

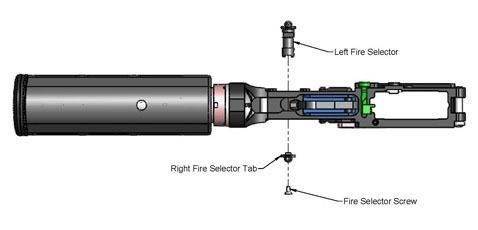

The POF-USA Gas Piston Operating System has an adjustable gas block that controls the amount of gas that is used to cycle the bolt carrier.

The notched side of the Gas Plug denotes that it is in NORMAL Mode when it is facing up. The rifle should cycle normally with most commercial ammunition.

Depress the gas plug detent; rotate the Gas Plug 45° so the gas plug detent is facing at a 45° angle, this denotes that the Gas Plug is in ADVERSE Mode using less gas to compensate for some ammunition.

Depressing the detent and rotating to the 90° position denotes that the Gas Plug is in OFF Mode. This shuts off the gas from the gas block completely and causes the rifle to function as a single-shot rifle.

By depressing the gas plug detent and rotating the Gas Plug 180° from NORMAL Mode, the smooth side of the Gas Plug is now facing up. The firearm is now in SUPPRESSED Mode. Gas in this mode is restricted to compensate for the added backpressure from a suppressor.

A second SUPPRESSED Mode setting is available with an increased gas flow which may be required with some suppressors. Depress the gas plug detent and rotate the smooth face to a 45° angle, this denotes that the Gas Plug is in the SUPPRESSED 2 mode.

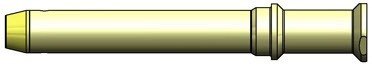

P-308 A2-Style Buffer

5.31″ overall length

P-308 A2-Style Action (Buffer) Spring

~12.5-12.75″ free length — 38-39 coils

![]()

“MIL-SPEC” A2-Style Buffer

5.91″ overall length

“MIL-SPEC” Action (Buffer) Spring

~12.5-12.75″ free length — 43-44 coils

![]()

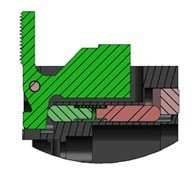

Replacement Ambidextrous Bolt Release kits can be ordered HERE.

After each shooting session or 250 rounds, whichever comes first, or whenever your firearm has been exposed to sand, dust, extreme humidity, condensation, immersion in water, or other adverse conditions; disassemble, clean, and lubricate your firearm.

Contact Technical Support [email protected] or if you do not have access to email, you can call them at 623-561-9572. When contacting Technical Support always know the Serial Number of the firearm, the brand and type of ammo being used, the brand of magazine being used, and the setting of the gas system when your malfunction occurred.

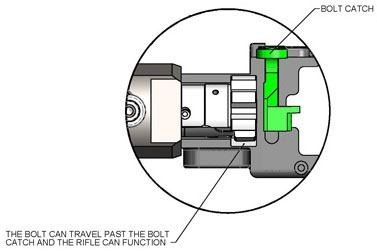

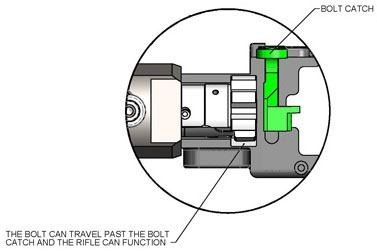

The Bolt Carrier Group (BCG) on the Revolution PD, Revolution DI, and Rogue, requires a longer stroke in order to eject .308 WIN cartridges from the Upper Receiver.

Because of this, these firearm models use a proprietary (longer) Buffer Tube as well as a proprietary Buffer Spring.

STANDARD LENGTH AR15/M16 CARBINE BUFFER TUBES (RECEIVER EXTENSIONS), AND BUFFER/ACTION SPRINGS WILL NOT WORK IN THE REVOLUTION PD, REVOLUTION DI, OR ROGUE MODELS. DO NOT USE THEM, THEY WILL NOT WORK, AND YOU MAY DAMAGE YOUR FIREARM.

Download/view the file below for a visual representation of the correct Buffer Tube and Buffer Spring.

After each shooting session, at regular intervals, or whenever your firearm has been exposed to sand, dust, extreme humidity, condensation, immersion in water, or other adverse conditions; disassemble, clean, and lubricate it using the techniques shown in the videos below.

NOTE: Excessive lubricant will attract dust and debris. Excessive lubricant may congeal in cold weather and can interfere with the safe operation and reliable function of the firearm.

Note: This Gas Block will have a minimum of 9 positions, including the fully closed “off” positions. Your gas block may have 1 or 2 additional open positions. By design, there are 3 different tools you might use to adjust your Regulator. The first is the custom Wrench provided with the gas block. It is designed with a finger loop that will also allow it to be attached to your key chain. It also is small enough for storage in many grips. The custom Wrench has a unique shape because it has been optimized for use with POF-USA handguards. However, it can be used if you have installed your DIctator™ with a handguard that does not extend past the Gas Block. The second method is a 3/32” hex wrench. The third is a flat head screwdriver.

After extended use, it may become difficult to adjust the Regulator. Below are the instructions for disassembly and cleaning.

Note: This diagram may be referenced for part descriptions and information.

After each shooting session or 250 rounds, whichever comes first, or whenever your firearm has been exposed to sand, dust, extreme humidity, condensation, immersion in water, or other adverse conditions; disassemble, clean, and lubricate your firearm.

Please download the Attached PDF to view the POF-USA Fastener Reference Guide and Suggested Tool List.

POF-USA only recommends the use of Magazines that have anti-tilt followers in any of our .308 WIN, 6.5 Creedmoor, and 6MM Creedmoor caliber Firearms. Currently the only magazines that have anti-tilt followers are:

The use of any other Magazines may cause feeding or cycling issues.

POF-USA only recommends the use of Magazines that have anti-tilt followers in any of our 5.56x45 NATO and 300 AAC Blackout caliber Firearms. Here are three examples of recommended Magazines that have anti-tilt followers.

POF-USA has been manufacturing firearms and firearm components since 2002. Through extensive testing and use we have learned that almost any machine including all firearms will have certain parts that could occasionally require maintenance, adjustments or replacement. “Wearable” or “Consumable” parts are those parts that by their very nature, through use (functioning) will not maintain absolute factory specifications forever and will need to be monitored periodically for functionality and safety. Some of these parts may have a finite life cycle which could be affected by use, abuse, or maintenance.

To address these parts on our products, it is recommended that a POF-USA firearm must be disassembled and inspected by a certified POF armorer at least annually. Many of the problems that the factory has encountered with customer’s returned firearms involve these “Wearable” or “Consumable” parts and or improper maintenance or cleaning.

Springs are very important to the safe and reliable operation of any firearm. They tend to be one of the most overlooked parts when performing maintenance. When they become worn through use or age they tend to anneal or take a set (become weak). This can change or adversely affect the operation or reliability of the firearm. In addition, any spring can be damaged, weakened, worn, or broken based on the use or abuse of the firearm and therefore should be inspected regularly and replaced as needed.

Extractors are a high use component that must function correctly every time the firearm feeds or extracts a cartridge from the chamber to complete the cycles of operation. Because of this they are considered a “Wearable” part and should be inspected regularly and replaced as needed.

Ejectors are also a high use component that must function correctly every time the firearm ejects a cartridge from the chamber. Because of this they are considered a “Wearable” part and should be inspected regularly and replaced as needed.

Op-Rods operate any time the firearm is cycled. Again, depending on the use or abuse of the firearm this part can be subjected to high impact stress and should be inspected regularly and replaced as needed.

The Firing Pin contacts the cartridge primer anytime a round is loaded and anytime the firearm is fired. This can cause impact stress to the face of the Firing Pin and therefore it should be inspected regularly and replaced as needed.

A Cam Pin is a crucial component that operates every time the firearm is cycled and is the main component that locks and un-locks the action. This part is a high cycle component and therefore should be inspected regularly and replaced as needed.

Our Service Department maintains a full complement of replacement parts. Even though most gunsmiths have the knowledge, training, and the ability to make necessary repairs to your firearm, the skill and workmanship of any particular 3rd party gunsmith is totally beyond our control.

Should your firearm ever require service, we strongly recommend that you return it to POF-USA. A firearm is a precision instrument, and some replacement parts will require individual fitting to ensure correct operation. A wrong part, improper fitting, or incorrect mechanical adjustment may result in an unsafe condition or dangerous malfunction, damage to the firearm, or cause possible serious injury to the shooter or others.

POF-USA parts may only be installed in conjunction with: 1) Other parts that were designed and/or sold by POF-USA or 2) Parts that adhere to the safety and functional dimensional requirements of the M16, M4 carbine, or any subsequent variant military specifications or data packages.

DPMS LR-308 Carbine Buffer - 2.5″ overall length

DPMS LR-308 Carbine Buffer Spring

~10.25-10.5″ free length — 29-30 coils

Mil-spec AR-15 Carbine Buffer - 3.25″ overall length

~12.5-12.75″ free length — 38-39 coils

![]()

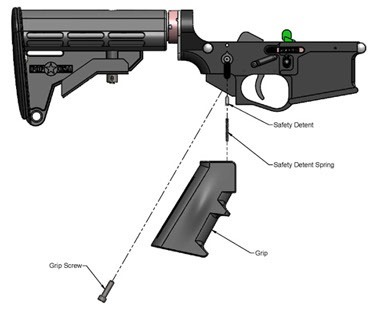

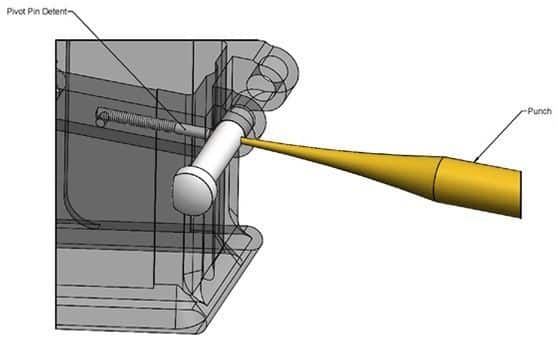

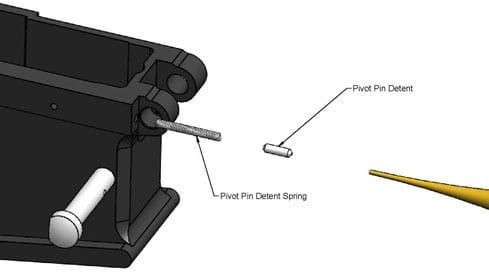

1. Place Pivot Pin in the open position.

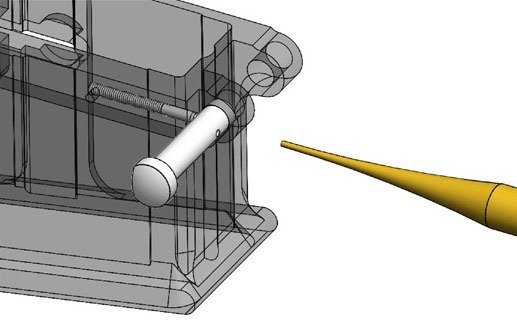

2. Insert 1/16″ (or smaller) punch or equivalent into Pivot Pin hole and depress Pivot Pin Detent.

3. Slightly pull out the Pivot Pin while removing punch.

4. Fully remove the Pivot Pin slowly. Remove the Pivot Pin Detent and Pivot Pin Detent Spring.

NOTE: Be sure not to lose Pivot Pin Detent under spring pressure. Point the lower receiver down onto a table before removing the Pivot Pin to catch.

The PSG 22 is a short-barreled blow back operated 22 LR pistol. It is chambered for and designed to properly function with the .22 caliber Long Rifle rimfire cartridge. We only recommend the use of high velocity or hyper-velocity ammunition, manufactured to U.S. industry standards, in the PSG 22 for optimal function.

Due to its blow-back operation, a fast cycle of the action is required to achieve proper ejection, extraction and hammer reset. When we say "fast cycle" we are talking about the amount of burnt powder a fired case ignites to cycle back the bolt carrier. The PSG 22 needs as much gas pressure as possible to eject, extract, reset the hammer, and feed a new round, much like other 22 LR pistol.

Low pressure, lower powered, or low quality ammunition is often inconsistent and anything below High velocity will struggle to cycle properly when not fired suppressed.

POF-USA recommends a break-in of around 500 rounds of high velocity such as those listed on the recommended ammunition list.

BRAND | TYPE |

|---|---|

| Remington | |

| Federal | |

| CCI | |

| Aguila |

If access to high velocity is not available, the use of standard velocity should suffice, but please avoid most match loads as they are very underpowered.

In many cases some subsonic ammunition has more pressure than some match loads. It is the nature of a match 22lr round to be sub-sonic as the bullet will stabilize better.

After the break-in period is complete the gun should run most all types of ammo. As is the case with most all 22lr firearms they are all independently picky.

Some experimenting will be necessary to find the best combo for your pistol.

Your pistol will likely vary from any other that you pick up off the shelf. Even box to box, 22lr ammunition varies greatly.

The PSG 22 will also have issues cycling subsonic ammunition with the use of a suppressor. There is No guarantee that it will function properly WITHOUT a suppressor.

It takes time for some springs in this weapon to set and have a long life. This is not a .223 or a .308 where the bolt moves rapidly to take care of this in a few shots. It takes extra time with a 22lr.

BRAND | TYPE |

|---|---|

| Winchester |

|

| Federal |

|

| CCI |

|

POF-USA only recommends the use of factory new ammunition loaded in accordance with U.S. industry practice and cannot offer any advice or tips regarding hand loaded or

reloaded ammunition. Reloading is a science and improperly loaded ammunition can be extremely dangerous. Damages due to high pressure, reloaded, or non-standard ammunition is not covered under warranty.

Use only high-quality, original, factory-manufactured ammunition. Do not use cartridges that are dirty, wet, corroded, bent, or damaged. Do not oil cartridges. Do not spray aerosol-type lubricants, preservative, or cleaners directly onto cartridges or where excess spray may flow into contact with cartridges. Lubricant or other foreign matter on cartridges can cause potentially dangerous ammunition malfunctions. Use only ammunition of the caliber for which your firearm is chambered. The proper caliber is permanently engraved on your barrel; never attempt to use ammunition of any other caliber.

Death, serious injury and damage can result from the use of wrong ammunition; bore obstructions, powder overloads, or incorrect cartridge components. Always wear eye protection and hearing protection while discharging your firearm.

ONLY USE FACTORY AMMUNITION LOADED TO U.S. INDUSTRY STANDARDS

POF-USA SPECIFICALLY DISCLAIMS ANY RESPONSIBILITY FOR ANY DAMAGE OR INJURY WHATSOEVER OCCURING IN CONNECTION WITH, OR AS A RESULT OF, THE USE IN POF-USA FIREARMS OF FAULTY, OR NON-STANDARD, OR “REMANUFACTURED”, OR HAND LOADED (RELOADED) AMMUNITION, OR OF CARTRIDGES OTHER THAN THOSE FOR WHICH THE FIREARM WAS ORIGINALLY CHAMBERED.

DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS, OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM, AND OTHER SERIOUS PHYSICAL INJURY. MAINTAIN ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE. SHOOTING OR CLEANING FIREARMS MAY EXPOSE YOU TO LEAD.

It is important to note that the ejector for this platform is the left side feed lip, just like every other firearm that uses 10/22 style magazines.

Below are notes regarding our results with PSG 22 compatible magazines.

Most consistent but should be cleaned on a regular basis. Factory spring tension can be inconsistent. If the magazine is not dropping free it is due to inconsistencies in the mold of the magazine. A light 30 sec sanding on each side of the mag will reveal the high spots and then the mag will drop free no problem.

Known for inconsistent feeding and feeding related issues. The springs are inconsistent and get bound up and just in general are not linear. The only solutions for this are the quick fixes found online with a quick google search of BX-25 feeding issues or just trying out several mags till you find one that works well. Also, the ejector on this magazine is the smallest ejector on any mag we have tested. This leads to issues with ejection. The BX-25 is also the narrowest magazine and has side to side play.

Same issues with spring tension as BX-25. When buying new ones you can usually break it in by loading the magazine and letting set for 48 hours, unloading and repeat. Unfortunately, these mags are friction welded together so cleaning them is not really an option. These magazines tend to feed well and also have the biggest ejector out of any of the mags that we have tested.

Have plastic feed lips and are not recommended. Any 10/22 magazine with plastic feed lips like the old Ramlines and Promag mags are also not recommended. The plastic feed lips wears out due to the feed lips doubling as the weapons ejector.

Very smooth-running magazine, no spring tension issues in our experience. This magazine also has a very large ejector and is the tightest fitting in our mag well. They are friction welded and they are not very consistent, but they always lean on the wider side.

Ours had horrible spring tension issues and we never could get the rounds to present well and could not do much testing with it.

In testing a variety of the Promag magazines, we noticed that every mag had different feed lips and ejectors. This caused major feeding and ejection issues. We never could get the rounds to feed and eject consistently and could not do much testing with them.

Any other magazines on the market we have not had the opportunity to test.

This maintenance supplement should help address all cleaning and maintenance issues with your PSG 22 pistol.

CLICK HERE TO DOWNLOAD THE PSG 22 MAINTENANCE & CLEANING SUPPLEMENT.

After each shooting session or 250 rounds, whichever comes first, or whenever your firearm has been exposed to sand, dust, extreme humidity, condensation, immersion in water, or other adverse conditions; disassemble, clean, and lubricate your firearm.

CLEANING FIREARMS, OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM, AND OTHER SERIOUS PHYSICAL INJURY. MAINTAIN ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE. SHOOTING OR CLEANING FIREARMS MAY EXPOSE YOU TO LEAD.

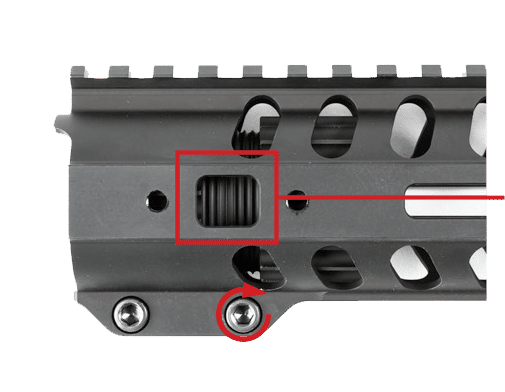

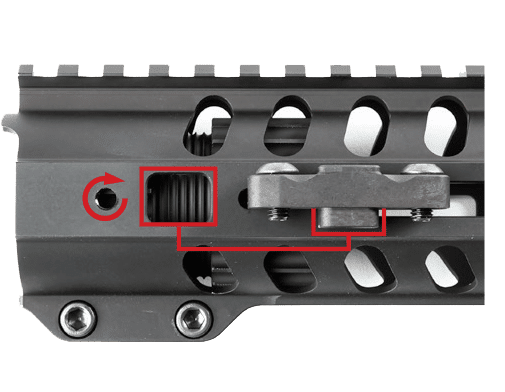

The Renegade Plus, Revolution DI, Rogue, Prescott, Minuteman, and Wonder series of Firearms use a unique mounting and locking system for the Handguard. The narrow profile Handguard is slipped over the barrel nut and locked horizontally into place using two QD Sling Mount blocks: one on the right side and one on the left side. Additionally, two Clamp Screws located at the bottom of the Handguard are tightened to effectively clamp the Handguard into place.

Once the Handguard is slid into position the cutout in the barrel nut should be visible in the window of the Handguard as shown here.

The square “block” on the QD Sling Mount will fit into the window of the Handguard and “lock” into the barrel nut. While holding the block forward against the barrel nut, the two Screws are then tightened on the QD Sling Mount block to 15 inch-pounds. This process must be followed on both the right and left side of the firearm.

Transition from V1 to V2 Bolt and Firing Pin for all Revolution and Rogue Firearms.

The Revolution PD, Revolution DI, Prescott, and Rogue bolt has been redesigned. Due to the nature of the redesign, the first version (V1) of the bolt and firing pin will not be compatible with the current version (V2) of the Bolt and Firing Pin.

Download/view the file below for a visual representation and explanation of and for the differences.

POF-USA Charging Handles and Mil-Spec AR-15 charging handles are compatible with the Revolution and Rogue platforms. Some other manufacturer's charging handles may not be compatible with the Revolution and Rogue platforms due to them using different internal geometry than Mil-Spec. This difference can cause the carrier key to impact the channel of the charging handle resulting in damage to the charging handle and/or the firearm in the indicated area.

The Revolution platform is a small frame AR-type firearm that is chambered in .308 WIN, 6.5 Creedmoor, or 6MM Creedmoor. With the help of customer feedback and internal testing we have discovered that the orientation of the Extractor Spring is important to the functioning/cycling of the weapon. If you experience jams and ejection failures, especially after cleaning the bolt, you should re-check the orientation of the Extractor Spring. The Extractor Spring has a small end and a large end. If the small end of the spring is placed into the pocket of the extractor, the spring can work loose and either sit at an angle or completely come out of the pocket. The result is malfunctioning in extraction and feeding.

The following installation process should only be performed by a certified POF-USA Armorer or gunsmith. Please contact a certified POF-USA Armorer or gunsmith for assistance.

POF-USA parts may only be installed in conjunction with: 1) Other parts that were designed and/or sold by POF-USA or 2) Parts that adhere to the safety and functional dimensional requirements of the M16, M4 carbine, or any subsequent variant military specifications or data packages.

Trigger components must be cleaned and maintained every 250 rounds, or after every shooting session, whichever comes first. Failure to properly clean and maintain the firearm and its components according to the cleaning procedure found in the support section of www.pof-usa.com can lead to damage to the firearm, bodily injury or death to the shooter or bystanders.

POF-USA does not recommend the use of this drop-in trigger in any 9MM, 40 S&W, 45 ACP, 10MM, or any other Pistol Caliber Firearm. The use of this drop-in trigger in any Pistol Caliber Firearm can lead to damage to the trigger, the firearm, and cause bodily injury or death to the shooter or bystanders. The use of this drop-in trigger in any Pistol Caliber Firearm will VOID the triggers warranty.

CLEANING FIREARMS, OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM, AND OTHER SERIOUS PHYSICAL INJURY. MAINTAIN ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE. SHOOTING OR CLEANING FIREARMS MAY EXPOSE YOU TO LEAD.

The following installation process should only be performed by a certified POF-USA Armorer or gunsmith. Please contact a certified POF-USA Armorer or gunsmith for assistance.

POF-USA parts may only be installed in conjunction with: 1) Other parts that were designed and/or sold by POF-USA or 2) Parts that adhere to the safety and functional dimensional requirements of the M16, M4 carbine, or any subsequent variant military specifications or data packages.

Trigger components must be cleaned and maintained every 250 rounds, or after every shooting session, whichever comes first. Failure to properly clean and maintain the firearm and its components according to the cleaning procedure found in the support section of www.pof-usa.com can lead to damage to the firearm, bodily injury or death to the shooter or bystanders.

POF-USA does not recommend the use of this drop-in trigger in any 9MM, 40 S&W, 45 ACP, 10MM, or any other Pistol Caliber Firearm. The use of this drop-in trigger in any Pistol Caliber Firearm can lead to damage to the trigger, the firearm, and cause bodily injury or death to the shooter or bystanders. The use this drop-in trigger in any Pistol Caliber Firearm will VOID the triggers warranty.

CLEANING FIREARMS, OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM, AND OTHER SERIOUS PHYSICAL INJURY. MAINTAIN ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE. SHOOTING OR CLEANING FIREARMS MAY EXPOSE YOU TO LEAD.

HOW ACCURATE ARE POF-USA FIREARMS?

All POF-USA 5.56x45 NATO, 300 Blackout, .308 WIN, 6.5 Creedmoor, and 6MM Creedmoor chambered Firearms are guaranteed to be MOA or better. Many variables are involved when shooting for accuracy or determining groups such as environment, ammo, optics, and individual shooter ability.

Can your 5.56 NATO Barrels shoot both .223 Remington and 5.56×45 NATO ammunition?

Yes. Our 5.56x45 Barrels are chambered using a 5.56 NATO reamer, which allows the use of both 5.56x45mm NATO and .223 Remington ammunition.

Can your .308 WIN Barrels shoot both 7.62x51 NATO and .308 WIN ammunition?

Yes. Our 308 barrels are chambered using a .308 Win reamer which allows the use of both .308 Winchester and 7.62×51 mm NATO ammunition.

Can I shoot steel-cased ammunition, like Wolf, in my POF-USA firearm?

Yes, in fact POF-USA does a lot of testing with WOLF ammo. However, it is important to remember to thoroughly clean the throat area of the chamber after a session with steel-cased ammo.

POF-USA only recommends the use of factory new ammunition loaded in accordance with U.S. industry practice and cannot offer any advice or tips regarding hand loaded or

reloaded ammunition. Reloading is a science and improperly loaded ammunition can be extremely dangerous. Damages due to high pressure, reloaded, or non-standard ammunition is not covered under warranty.

Use only high-quality, original, factory-manufactured ammunition. Do not use cartridges that are dirty, wet, corroded, bent, or damaged. Do not oil cartridges. Do not spray aerosol-type lubricants, preservative, or cleaners directly onto cartridges or where excess spray may flow into contact with cartridges. Lubricant or other foreign matter on cartridges can cause potentially dangerous ammunition malfunctions. Use only ammunition of the caliber for which your firearm is chambered. The proper caliber is permanently engraved on your barrel; never attempt to use ammunition of any other caliber.

Death, serious injury and damage can result from the use of wrong ammunition; bore obstructions, powder overloads, or incorrect cartridge components. Always wear eye protection and hearing protection while discharging your firearm.

ONLY USE FACTORY AMMUNITION LOADED TO U.S. INDUSTRY STANDARDS

POF-USA SPECIFICALLY DISCLAIMS ANY RESPONSIBILITY FOR ANY DAMAGE OR INJURY WHATSOEVER OCCURING IN CONNECTION WITH, OR AS A RESULT OF, THE USE IN POF-USA FIREARMS OF FAULTY, OR NON-STANDARD, OR “REMANUFACTURED”, OR HAND LOADED (RELOADED) AMMUNITION, OR OF CARTRIDGES OTHER THAN THOSE FOR WHICH THE FIREARM WAS ORIGINALLY CHAMBERED.

DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS, OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM, AND OTHER SERIOUS PHYSICAL INJURY. MAINTAIN ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE. SHOOTING OR CLEANING FIREARMS MAY EXPOSE YOU TO LEAD.

Why doesn’t POF-USA offer chrome-lined barrels?

Our Barrels are nitride heat-treated to a case hardness of 68 - 70 HRC. Our barrels shoot consistently better groups than chrome-lined barrels. Our Barrels are easier to clean and do not copper foul heavily like chrome-lined barrels. On a traditional chrome lined and phosphate mil-spec barrel, the phosphate will rust if it is not oiled often. Chrome will eventually start to crack and flake as the barrel heats up and cools down, especially at higher round counts, leading to accuracy and head space issues.

| BARREL | THREAD PITCH | TWIST RATE |

| 12.5" .308 WIN NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:10 |

| 13.75" .308 WIN NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:10 |

| 14.5" .308 WIN NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:10 |

| 16.5" .308 WIN NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:10 |

| 18.5" .308 WIN NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:10 |

| 12.5" .308 WIN STAINLESS STEEL ROGUE BARREL | 5/8X24 | RH 1:8 |

| 16.5" .308 WIN STAINLESS STEEL ROGUE BARREL | 5/8X24 | RH 1:8 |

| 20" 6.5 CREEDMOOR NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:8 |

| 22" 6MM CREEDMOOR NITRIDE REVOLUTION BARREL | 5/8X24 | RH 1:7.5 |

| 10.5" 5.56 NATO NITRIDE BARREL | 1/2X28 | RH 1:8 |

| 13.75" 5.56 NATO NITRIDE BARREL | 1/2X28 | RH 1:8 |

| 16.5" 5.56 NATO NITRIDE BARREL | 1/2X28 | RH 1:8 |

| 10.5" 300 BLACKOUT NITRIDE BARREL | 5/8X24 | RH 1:7 |

| 13.75" 300 BLACKOUT NITRIDE BARREL | 5/8X24 | RH 1:7 |

| 10.5" 350 LEGEND NITRIDE BARREL | 5/8X24 | RH 1:16 |

| 16.5" 350 LEGEND NITRIDE BARREL | 5/8X24 | RH 1:16 |

| 7.75" 22 LR NITRIDE PSG 22 BARREL | 1/2X28 | RH 1:16 |

| 8.25" 9MM NITRIDE PHOENIX BARREL | 1/2X28 | RH 1:10 |

| 16.25" 9MM NITRIDE PHOENIX BARREL | 1/2X28 | RH 1:10 |

| 12.5" 9MM NITRIDE TOMBSTONE BARREL | 1/2X28 | RH 1:10 |

| 16.5" 9MM NITRIDE TOMBSTONE BARREL | 1/2X28 | RH 1:10 |

POF-USA has been manufacturing firearms and firearm components since 2002. Through extensive testing and use we have learned that almost any machine including all firearms will have certain parts that could occasionally require maintenance, adjustments or replacement. “Wearable” or “Consumable” parts are those parts that by their very nature, through use (functioning) will not maintain absolute factory specifications forever and will need to be monitored periodically for functionality and safety. Some of these parts may have a finite life cycle which could be affected by use, abuse, or maintenance.

To address these parts on our products, it is recommended that a POF-USA firearm must be disassembled and inspected by a certified POF armorer at least annually. Many of the problems that the factory has encountered with customer’s returned firearms involve these “Wearable” or “Consumable” parts and or improper maintenance or cleaning.

Springs are very important to the safe and reliable operation of any firearm. They tend to be one of the most overlooked parts when performing maintenance. When they become worn through use or age they tend to anneal or take a set (become weak). This can change or adversely affect the operation or reliability of the firearm. In addition, any spring can be damaged, weakened, worn, or broken based on the use or abuse of the firearm and therefore should be inspected regularly and replaced as needed.

Extractors are a high use component that must function correctly every time the firearm feeds or extracts a cartridge from the chamber to complete the cycles of operation. Because of this they are considered a “Wearable” part and should be inspected regularly and replaced as needed.

Ejectors are also a high use component that must function correctly every time the firearm ejects a cartridge from the chamber. Because of this they are considered a “Wearable” part and should be inspected regularly and replaced as needed.

Op-Rods operate any time the firearm is cycled. Again, depending on the use or abuse of the firearm this part can be subjected to high impact stress and should be inspected regularly and replaced as needed.

The Firing Pin contacts the cartridge primer anytime a round is loaded and anytime the firearm is fired. This can cause impact stress to the face of the Firing Pin and therefore it should be inspected regularly and replaced as needed.

A Cam Pin is a crucial component that operates every time the firearm is cycled and is the main component that locks and un-locks the action. This part is a high cycle component and therefore should be inspected regularly and replaced as needed.

Our Service Department maintains a full complement of replacement parts. Even though most gunsmiths have the knowledge, training, and the ability to make necessary repairs to your firearm, the skill and workmanship of any particular 3rd party gunsmith is totally beyond our control.

Should your firearm ever require service, we strongly recommend that you return it to POF-USA. A firearm is a precision instrument, and some replacement parts will require individual fitting to ensure correct operation. A wrong part, improper fitting, or incorrect mechanical adjustment may result in an unsafe condition or dangerous malfunction, damage to the firearm, or cause possible serious injury to the shooter or others.

POF-USA parts may only be installed in conjunction with: 1) Other parts that were designed and/or sold by POF-USA or 2) Parts that adhere to the safety and functional dimensional requirements of the M16, M4 carbine, or any subsequent variant military specifications or data packages.

Can I use a POF-USA Drop in Trigger in a Pistol Caliber firearm?

POF-USA does not recommend the use of any POF-USA Drop-in Triggers in any 9MM, 40 S&W, 45 ACP, 10MM, or any other Pistol Caliber Firearm. The use of a POF-USA Drop-in Trigger in any Pistol Caliber Firearm can lead to damage to the trigger, the firearm, and can cause bodily injury or death to the shooter or bystanders. The use of a POF-USA Drop-in Trigger in any Pistol Caliber Firearm will VOID the triggers warranty.

What magazines are shipped with Restricted State Models?

High-capacity Magazines are unavailable in certain parts of our country including Colorado, Connecticut, California, Hawaii, Maryland, Massachusetts, New Jersey, and New York.

All restricted state models will ship with a state-compliant magazine.

Can I return my purchase for a refund?

POF-USA offers a 30-day return policy on all items purchased directly from the factory. (Parts, Merchandise, Uppers).

How may I return a Rifle, Pistol, or lower receiver?

You will need to return serial numbered items to the dealer you purchased from. Refunds or exchanges of Serial Numbered items are at the discretion of the selling dealer.

The Rogue comes standard with a Low-Profile Gas Block. It is highly recommended that you install an adjustable gas block, such as the AR-15 Mid-Length Dictator, on your Rogue to properly cycle with a suppressor. Suppressors naturally increase back pressure. This pressure increases the cyclical rate of your Firearms Bolt Carrier Group (BCG). The Dictator Gas Block will allow you to regulate the Bolt Carrier Group (BCG) speed for best performance and optimal parts life. Please be aware of all risks by attaching a suppressor to your firearm.

Putting a suppressor on your firearm will increase the cycling rate of your Bolt Carrier Group (BCG) during extraction. This will cause unwanted malfunctions and increased wear on the system. POF-USA highly recommends using an Adjustable Gas System and Hydraulic Buffer to properly tune in your rifles cyclical rate. Please be aware of all risks by attaching a suppressor.

Learn how to adjust your Gas Piston System by clicking HERE.

Learn how to adjust your DIctator Gas Block by clicking HERE.

Hydraulic Buffers are designed and optimized for use with suppressors. Learn more about the KynSHOT Hydraulic Buffer by clicking HERE.

Please read the Tombstone 9MM Manual BEFORE attempting to handle, load or utilize the POF-USA Tombstone family of firearms.

Please read the Rogue & Prescott Manual BEFORE attempting to handle, load or utilize the POF-USA Light Weight Rogue family of firearms.

Please read the Revolution PD Manual BEFORE attempting to handle, load or utilize the POF-USA Revolution family of firearms.

Please read the Revolution DI Manual BEFORE attempting to handle, load or utilize the POF-USA Revolution DI family of firearms.

Please read the PSG 22 Manual BEFORE attempting to handle, load or utilize the POF-USA PSG 22 family of firearms.

Please read the Phoenix 9MM Manual BEFORE attempting to handle, load or utilize the POF-USA Phoenix 9MM family of firearms.

Please read the P19 Manual BEFORE attempting to handle, load or utilize the POF-USA P19 family of firearms.

Please read the P-415 Renegade + Manual BEFORE attempting to handle, load or utilize the POF-USA P-415 family of firearms.

Please read the P-415 Edge Manual BEFORE attempting to handle, load or utilize the POF-USA P-415 family of firearms.

Please read the P-308 EDGE Manual BEFORE attempting to handle, load or utilize the POF-USA P-308 family of firearms.

Please read the P-15 Renegade Manual BEFORE attempting to handle, load or utilize the POF-USA P-15 Renegade family of firearms.

Please read the P-15 Puritan Manual BEFORE attempting to handle, load or utilize the POF-USA P-15 Puritan family of firearms.

Please read the P-15 Minuteman & Wonder Manual BEFORE attempting to handle, load or utilize the POF-USA P-15 family of rifles and pistols.

Please read the P-15 Constable Manual BEFORE attempting to handle, load or utilize the POF-USA P-15 Constable family of firearms.

Please read the P-15 BASE Manual BEFORE attempting to handle, load or utilize the POF-USA P-15 BASE family of firearms.

Please read the LMR BASE Manual BEFORE attempting to handle, load or utilize the POF-USA LMR BASE family of firearms.

Use the P-15 BASE Upper Schematics Diagram to find out more about all the POF-USA components used to build your P-15 BASE Upper Receiver.

Use the P-15 Constable Upper Schematics Diagram to find out more about all the POF-USA components used to build your P-15 Constable Upper Receiver.

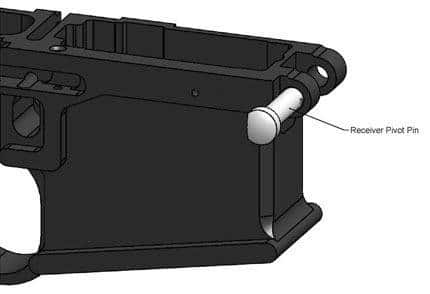

Check out the P-15 Lower Schematics Diagram to find out more about all the POF-USA components used to build your P-15 Lower.

Use the P-15 Minuteman Upper Schematics Diagram to find out more about all the POF-USA components used to build your P-15 Minuteman, P-15 Wonder, and P-15 Constable upper receiver.

Use the P-15 Puritan Upper Schematics Diagram to find out more about all the POF-USA components used to build your Puritan Upper Receiver.

Use the P-15 Renegade Upper Schematics Diagram to find out more about all the POF-USA components used to build your Renegade Upper Receiver.

Check out the P-308 Lower Schematics Diagram to find out more about all the POF-USA components used to build your P-308 Lower Receiver.

Use the P-308 Upper Schematics Diagram to find out more about all the POF-USA components used to build your P-308 Upper Receiver.

Check out the P-415 EDGE Upper Schematics Diagram to find out more about all the POF-USA components used to build your P-415 EDGE Upper.

Check out the P-415 Lower Schematics Diagram to find out more about all the POF-USA components used to build your P-415 Lower.

Check out the P-415 Renegade + Upper Schematics Diagram to find out more about all the components used to build your Renegade + upper.

Check out the Phoenix 9MM Lower Schematics Diagram to find out more about all the POF-USA components used to build your Phoenix 9MM Lower.

Use the Phoenix 9MM Upper Schematics Diagram to find out more about all the POF-USA components used to build your Phoenix 9MM firearm.

Check out the PSG 22 Lower Schematics Diagram to find out more about all the POF-USA components used to build your PSG 22 Lower.

Check out the PSG 22 Upper Schematics Diagram to find out more about all the POF-USA components used to build your PSG 22 UPPER.

Check out the Revolution DI Upper Schematics Diagram to find out more about all the POF-USA components used to build your Revolution DI upper.

Check out the Revolution Lower Schematics Diagram to find out more about all the POF-USA components used to build your Revolution Lower.

Check out the Revolution PD Upper Schematics Diagram to find out more about the components used to build your Revolution PD Upper.

Check out the Rogue Lower Schematics Diagram to find out more about all the POF-USA components used to build your Rogue Lower.

Check out the Rogue Upper Schematics Diagram to find out more about all the POF-USA components used to build your Rogue upper.

Check out the Tombstone 9MM Rifle Schematics Diagram to find out more about all the POF-USA components used to build your Tombstone rifle.

All Patriot Ordnance Factory, Inc. (POF-USA) products are manufactured using the finest quality materials and have a limited lifetime warranty. All POF-USA firearms are warrantied to be free from defective materials and workmanship. POF-USA will repair or replace only those parts as determined to be defective by the factory. This warranty is limited and does not extend to careless handling, abuse and misuse, unauthorized adjustments or modifications, use of improper ammunition, excessive or unreasonable use, rust or corrosion or barrel obstruction.

Altering or modifying parts is dangerous and will void the warranty. Your POF-USA firearm was manufactured to perform properly with the original parts as designed. It is your responsibility to make sure any parts you install are made for this firearm, installed correctly, and that neither the originals nor the replacement parts are altered or changed. Your POF-USA firearm is a complex precision tool with many parts that must operate correctly with other parts in order to maintain proper and safe operation. Putting your firearm together improperly or with incorrect or modified parts can result in a damaged firearm, serious personal injury, or death to you and/or others through malfunction. Always have a qualified armorer or gunsmith work on your POF-USA firearm systems or other firearms.

Shipping to and from our facilities, government fees, damages caused by failure to perform normal maintenance, sales outside the United States, damages due to high velocity, high pressure, reloaded, remanufactured, or other no non-standard ammunition, consequential or incidental damages and /or expenses, any unauthorized repair, modification, misuse, abuse, or alteration of the product is not covered by this warranty.

It is the responsibility of the owner to assure the weapon is properly maintained.

In order to help us assist you better, please register your firearm through our Warranty Registration Form. Warranty is established by registering online at: Warranty Registration - POF-USA (www.pof-usa.com).

For further technical assistance or to obtain warranty information on your POF-USA firearm, email our customer service team at [email protected].

To initiate a warranty claim, please visit: RMA – APB360/GunTRAC. Please be advised that by initiating the RMA process you acknowledge that the firearm/components being returned for warranty/repair/service falls under the limited lifetime warranty. If returning a firearm for service, please contact customer service prior to RMA acceptance. POF-USA will need to gather additional details, create a customer profile (PO) and place a credit card on file for services rendered. If the firearm/component does not meet the requirements of the limited lifetime warranty and requires service due to abuse, deferred maintenance and/or installation of third-party components the customer will be subject to shipping charges, a $75.00 per hour service fee, the cost of parts and applicable taxes. Prior to shipping, please remove all optics, lighting and or any third-party products from your firearm as POF-USA will not be liable for any possible damage that could be incurred during the shipping process.

"*" indicates required fields